About Rajendra Agarwal And Associates

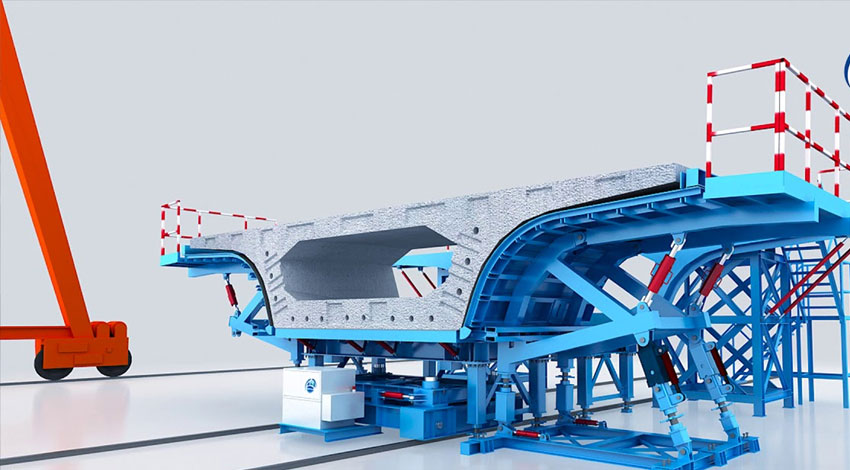

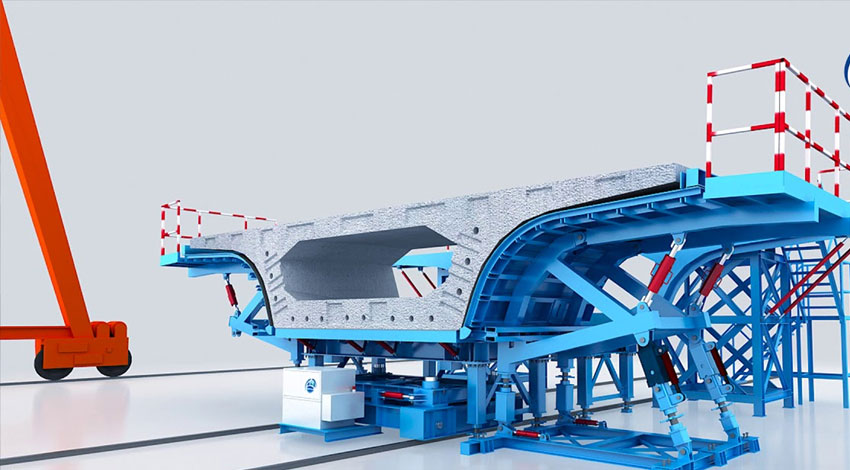

Underpass by Cut and Cover Method using Pre Cast Segments RH - Girder

- Home

- Underpass by Cut and Cover Method using Pre Cast Segments RH - Girder

The intersection of railway track and the road at the same level is referred to a level crossing. In the urban areas the level crossing are generally monitored by qualified railway personnel who monitor the train movement and close the level crossing gate to stop the interfering road traffic but such closing of gates leads to congestion in road traffic and also causes loss of time to road users. Road under bridge and road over bridge are considered as solutions for avoiding level crossings of roads and railway track. There are 3 main methods in construction of road under bridge. Box pushing method, Cut and cover method, Rolling technique using RH girder. In this we discuss about the implements, soil friction, effects required, capacity of jacks and there uses, skew angles and at square angles.

INTRODUCTION

With the increase of railways and roadways , there are bound to be few places wherethey intersect each other and as these intersects appear we have to provide few crossing betweenthem , traditionally we provide either an overpass or signal crossing in them , the majordrawbacks of these techniques are that they require a large amount of time to be constructed andduring this time the railway track

Box Pushing Method

Are to be shut down , and as the increasingly busy schedule ofthe railways its becoming more and more difficult to keep the tracks closed and on the otherhand the problem with traffic signals is that they come with a risk factor , signal crossing areprone to accidents , many of human Open excavation is carried out for construction of Thrust bed. The Thrust bed and Thrust Beam and keys are designed in R.C.C. to resist the required Thrustextorted by Jacking force and transfer it to soil at bottom and sides. In cohesivesoils even shallow piles are required to transfer the load. Provision for Jackingsupports is made by providing suitable Pockets in the bed to accommodate pinsupports. On completion of Jacking the thrust bed is utilized as floor bed, and soit is left in place.

Fabrication of Front Shield and Rear Shield

It is fabricated for cutting action and to provide support , to prevent caving in of soil. It is provided by anchoring steel plates on the face of bottom slab of RCC box to suitably distribute the jacking load

Box Casting And Pushing

The RCC Box is cast in segments of convenient lengths of Total pushing length. The Box section is designed as per IRS / IRC codes of practice for loading.Concrete grade normally kept as M-35

Pushing Operation of the Box

The purpose of pushing of Box is to form a horizontal opening below ground or through embankments, can say a tunnel, by providing precast box units underground or an embankment,without disturbing the overhead amenities, like traffic & structures. To reduce the frictionalresistance, a thin film of Grease and thick gauge plastic sheet is provided between the top of thethrust bed & Bottom of the Box. This is done before casting of the Bottom slab of the box. Aglossy Epoxy layer is also provided to reduce friction on the top and prevent the disturbance ofthe mass over box to